Why Us

Certifications

Our Products are Tested and Certified in accordance with International and National Standards from well established NABL Accredited Laboratories.

ISI Marked

For Electroplated Coatings of Copper

UL Listed

For Electroplated Coatings of Copper

IEC 62561-7:2018

For Earth Enhancing Compounds

CPRI

Short Circuit Current Test for Copper Bonded Rods, Pipes

ASTM B499:2014

For Copper Bonded Rods, Strips

IEC 62561-2:2018

For Copper Bonded Rods

TUV Rheinland

RoHS-2 2011/65/EU for Earth Enhancing Compounds

SGS

(TCLP) For Earth Enhancing Compounds

CIPET

Compression Test for Earth Pit Chambers

Quality Assurance

A well-established laboratory along with a dedicated quality check professional brings out the standard quality in each product segment. Various In-House Tests carried out are as follows

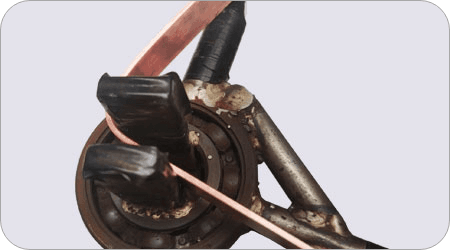

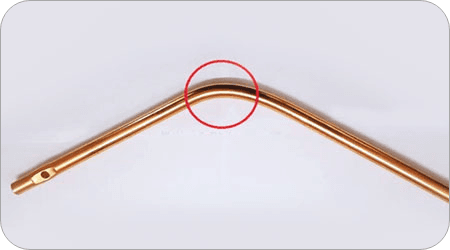

Bend Test

(As per clause 9.7.2 UL 467)

A length of the rod shall be rigidly held in a clamp or vise. A force shall be applied normal to the free end of the rod at a distance from the clamping device equal to 40 times the rod diameter. The application of force shall be such that the rod is permanently bent through a 30 degree angle.

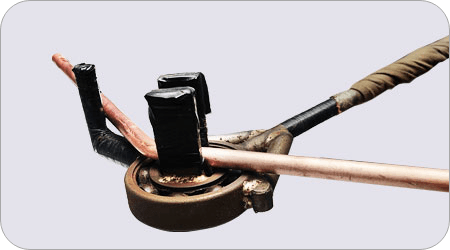

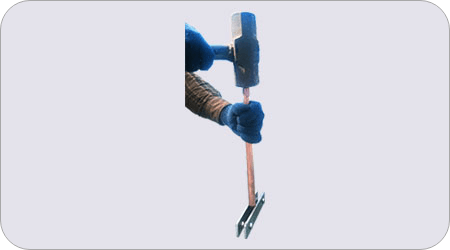

Adherence Test

(As per clause 9.7.1 UL 467)

A 457 mm (18 in) length of the rod with one end cut to a 45° point shall be driven between two steel clamping plates or the jaws of a vise set 1.02 mm (0.04 in) less than the diameter of the rod, so as to shear off sufficient metal to expose the bond between the coating and rod.

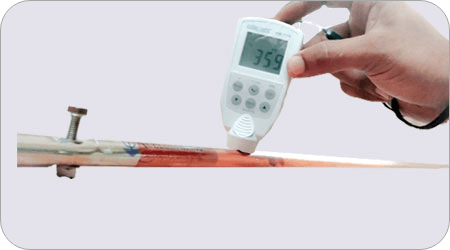

Coating Thickness Test

(As per clause 9.6.1 UL 467)

The thickness of a protective coating shall be determined by a reliable electronic or magnetic method, or by an electrochemical method.

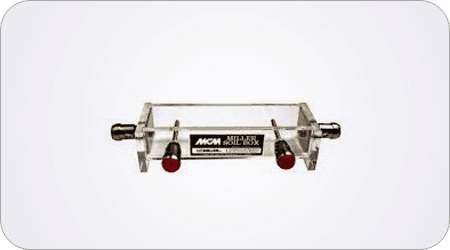

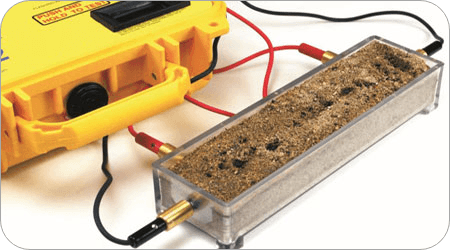

Resistivity of EarthEnhancing Compound

(As per clause 5.4 of IEC 62561-7:2018)

The four Electrode method is used to determine the resistivity of Earth Enhancing Compound as per ASTM G57-06 it is done with the aid of Standard Soil Box.

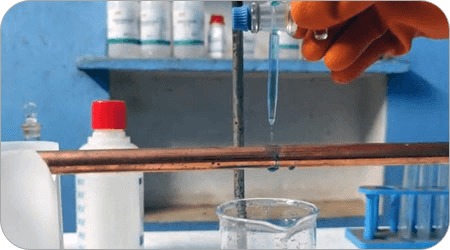

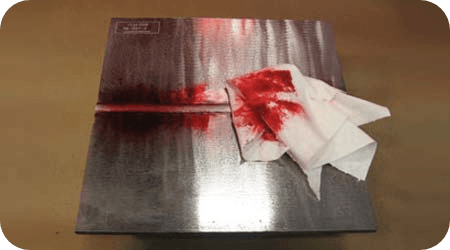

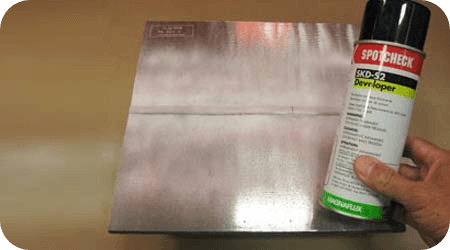

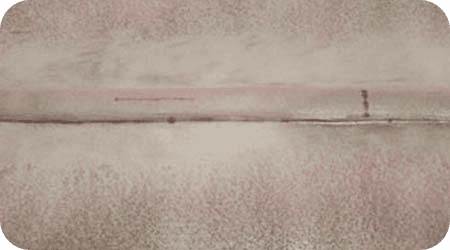

Dye Penetration Test

(As per ISO 3452-1:2013)

This method of non-destructive test is used to detect the cracks or pores that are developed in welded area. Surface is cleaned and liquid penetrant is sprayed over the welded area. After 15 minutes, excess penetrant is removed and developer is applied on the surface which will show any discontinuities in the surface including cracks or pores.

Applying Penetrant

Removing Penetrant

Applying Developer

Evaluating Indications